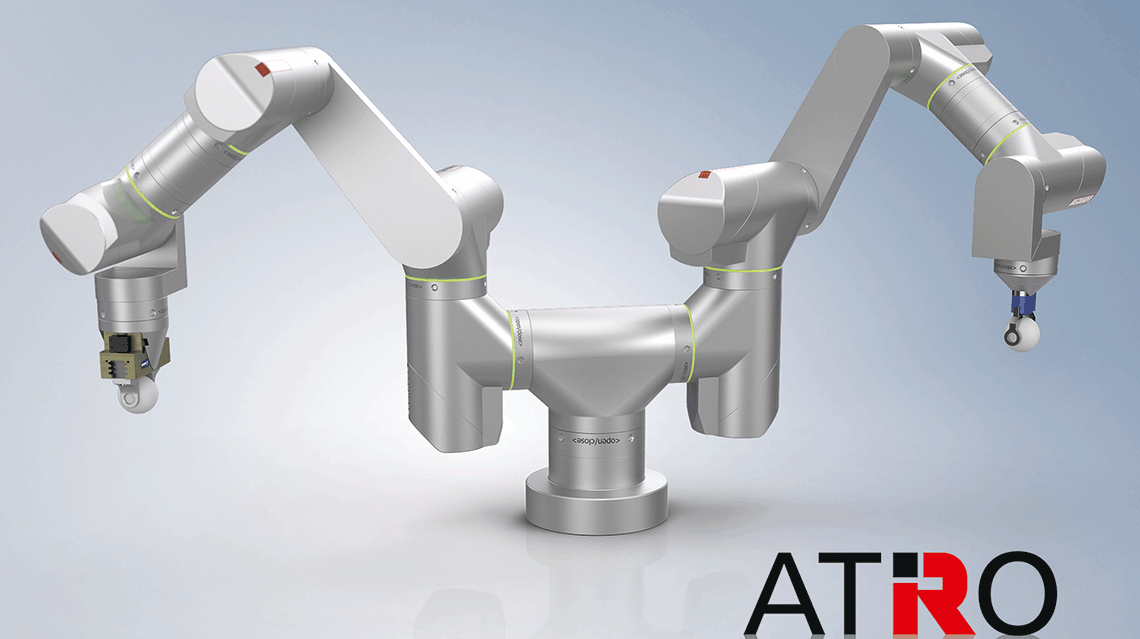

ATRO: Automation Technology for Robotics – the modular industrial robot system

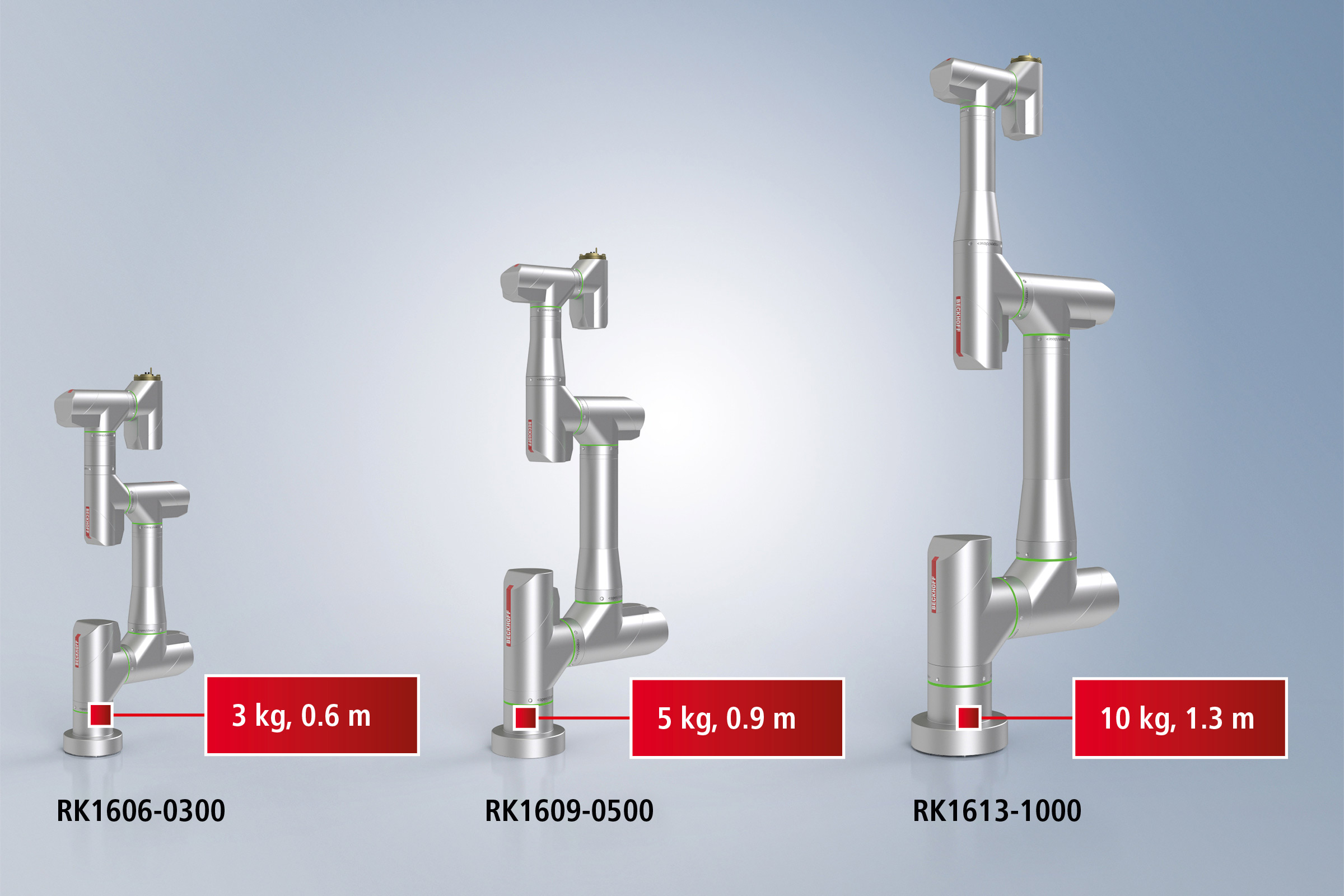

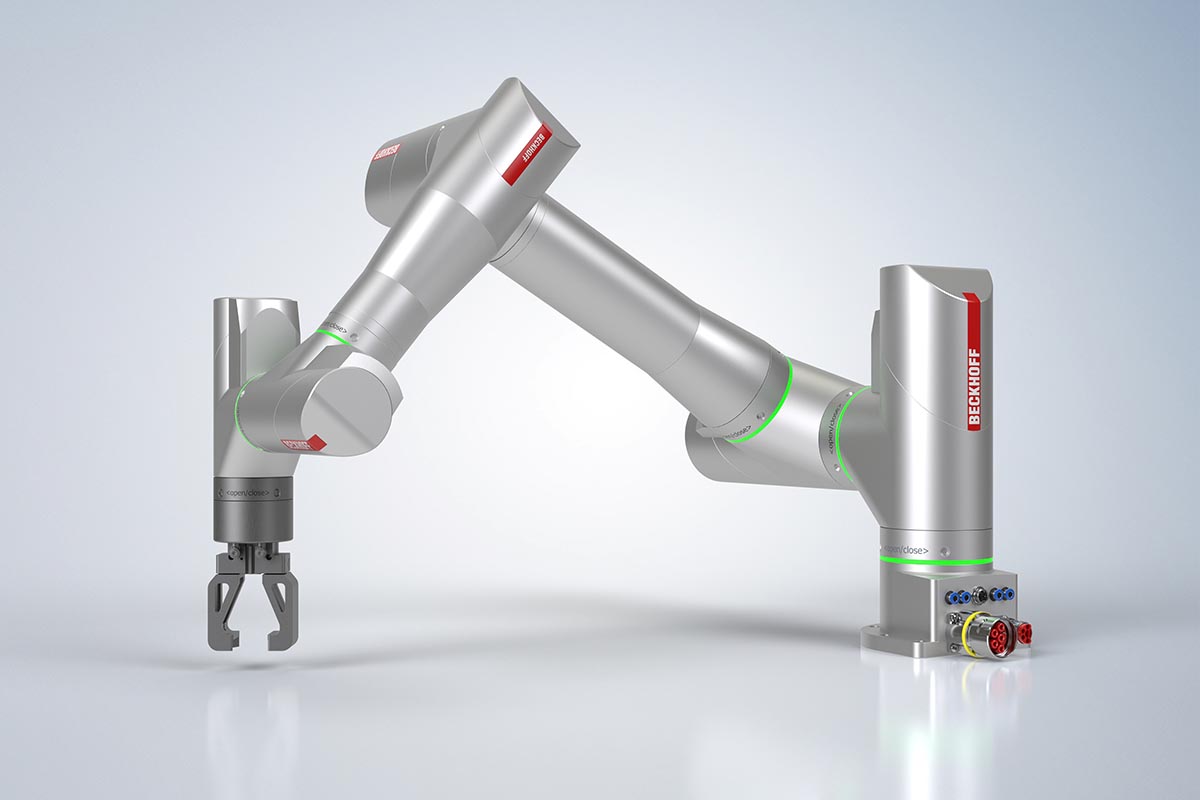

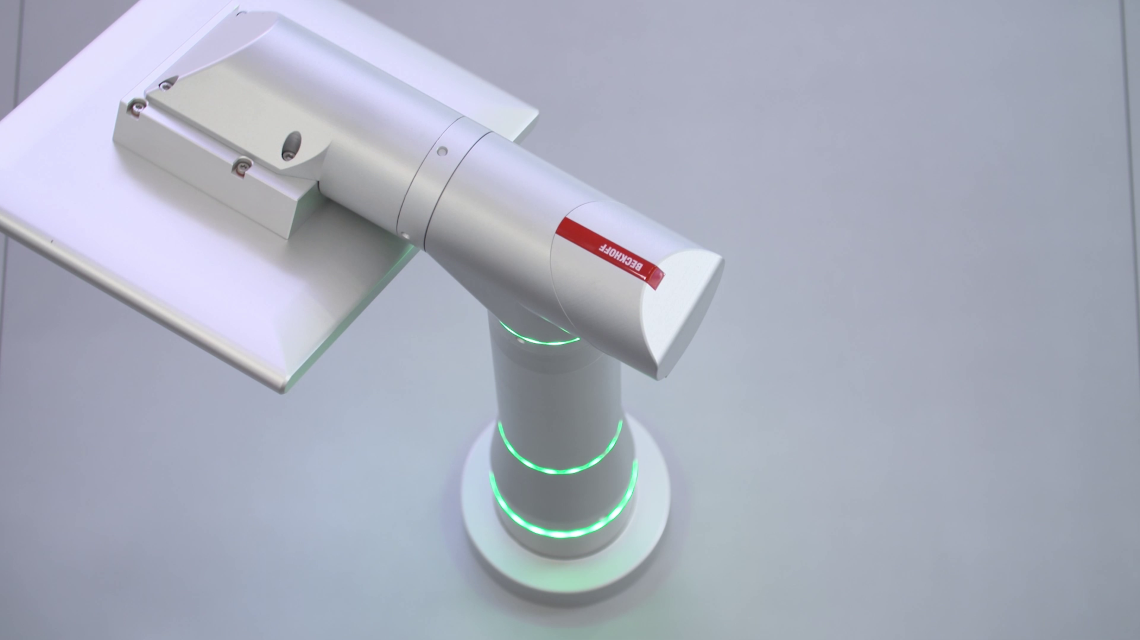

The new ATRO system from Beckhoff is a modular industrial robot system that can be used to assemble optimal robot structures for different applications on an individual and flexible basis. Standardized motor modules with integrated drive functionality, together with link modules in various designs and lengths, enable almost limitless combinations of mechanics. The complete integration of the control into the holistic TwinCAT control platform offers direct access to a wide range of proven automation functions.

This opens up an extensive range of individual options for users to implement their own kinematics, such as:

- 1-axis rotary indexing table with integrated power feed

- 2-axis tracking unit

- 3-axis delta robot

- 4-axis pick-and-place robot

- 5-axis palletizing robot

- 6-axis serial robot

- 7-axis system to increase the range/articulation for hard-to-reach areas

- multi-arm kinematics

Complete integration into the control platform

New Automation Technology: With the ATRO system, Beckhoff is once again living up to its ‘New Automation Technology’ claim. The development of modular robots – along with their full integration into the holistic control platform – both completes the Beckhoff portfolio and sets a new milestone in automation technology.

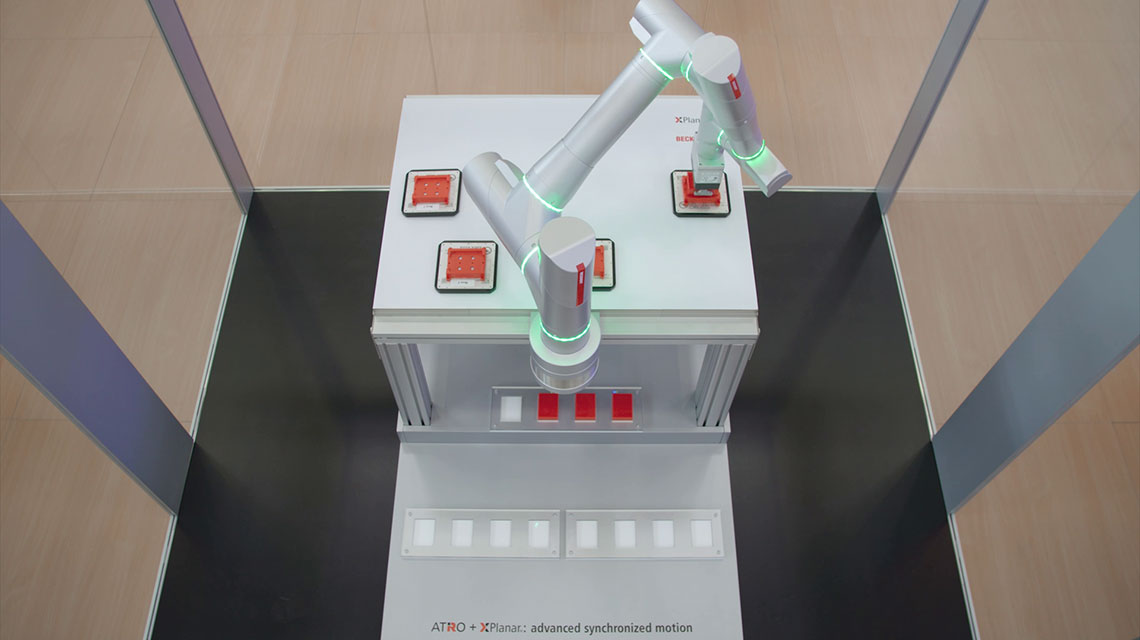

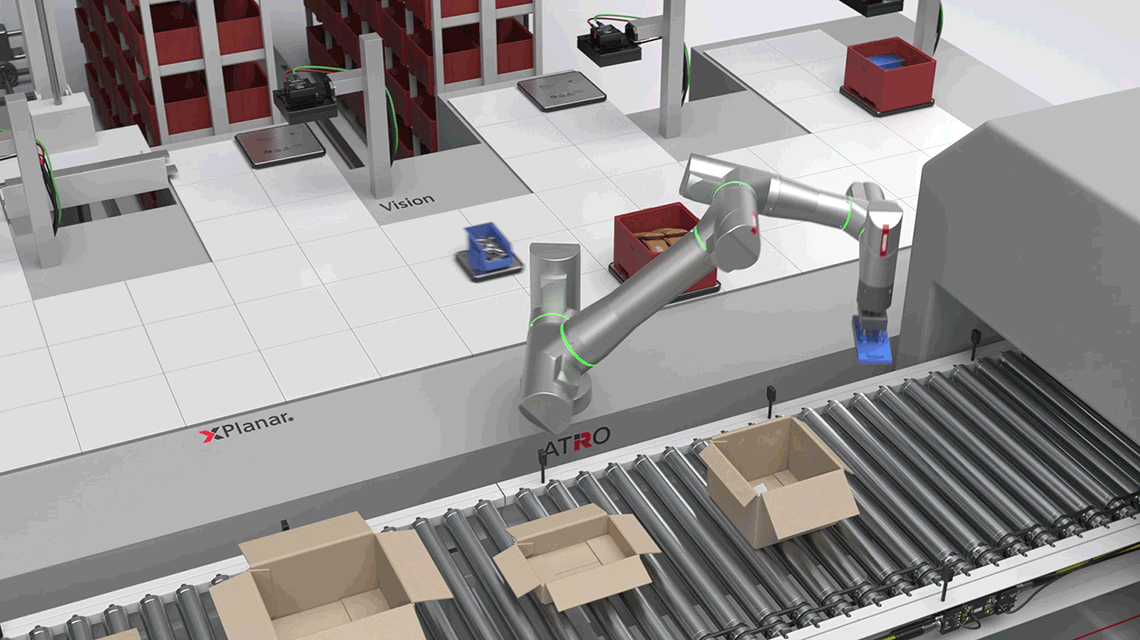

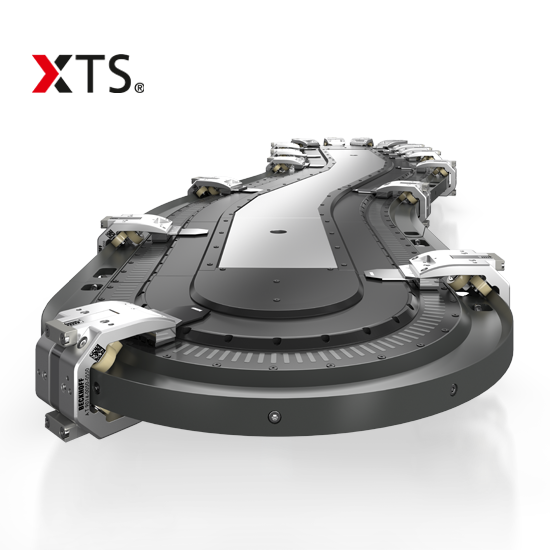

The machine’s performance is maximized by the direct integration of the robotics solution into motion control, safety, machine learning, IoT, analytics, vision, cloud engineering, and HMI, as well as through direct combinations with intelligent transport systems such as XPlanar and XTS. Another major advantage is that all components are fully networked with each other. This results in precise temporal synchronization, i.e. highly dynamic interactions between the systems can be performed during product transport. In addition, data can be mutually accessed in a natural way, thus simplifying configuration. The time and effort required for commissioning the robot is significantly reduced, allowing initial movements to take place in just a few minutes.

The new robotics solution ties in perfectly with the PC-based and EtherCAT-based control philosophy's holistic approach.

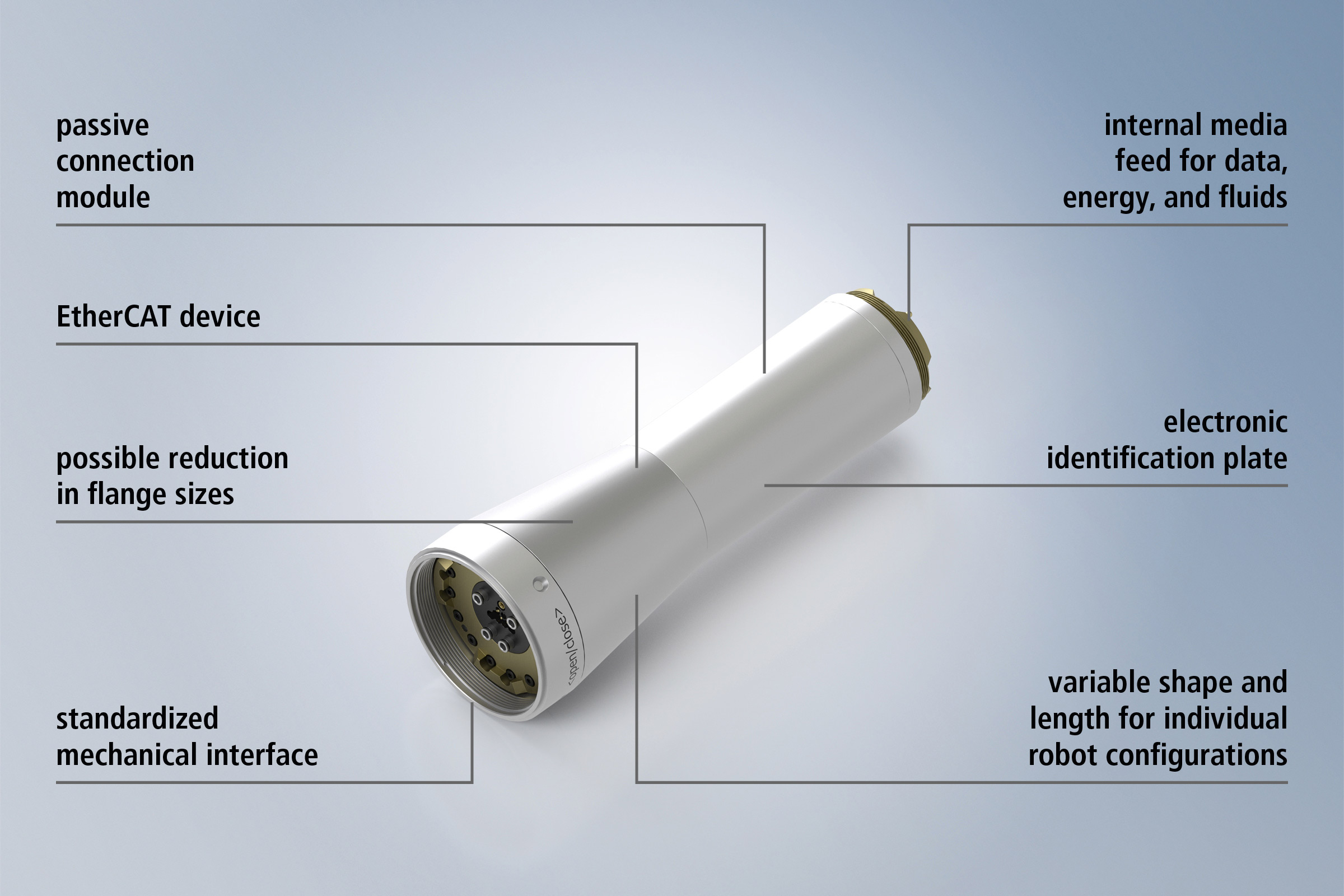

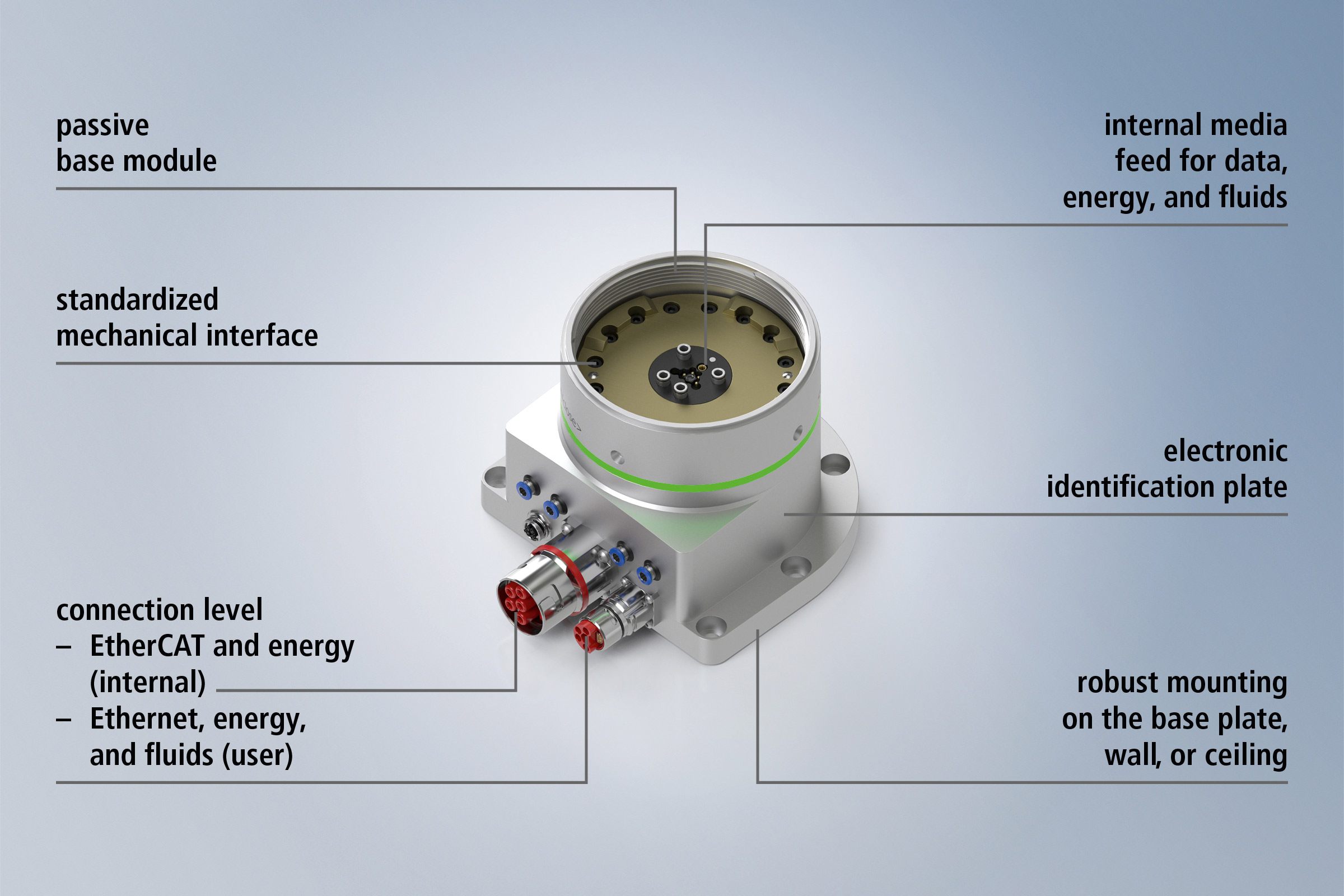

Modular design with standardized interfaces

The ATRO modular robotics system marks a real turning point in robot development. Its direct integration into the Beckhoff system solution allows machine builders to offer fit-for-production machines complete with fully integrated robotics and their own kinematics. The robot solution can be adapted precisely to the task: it has an unlimited number of axes and is freely scalable, modifiable, and expandable.

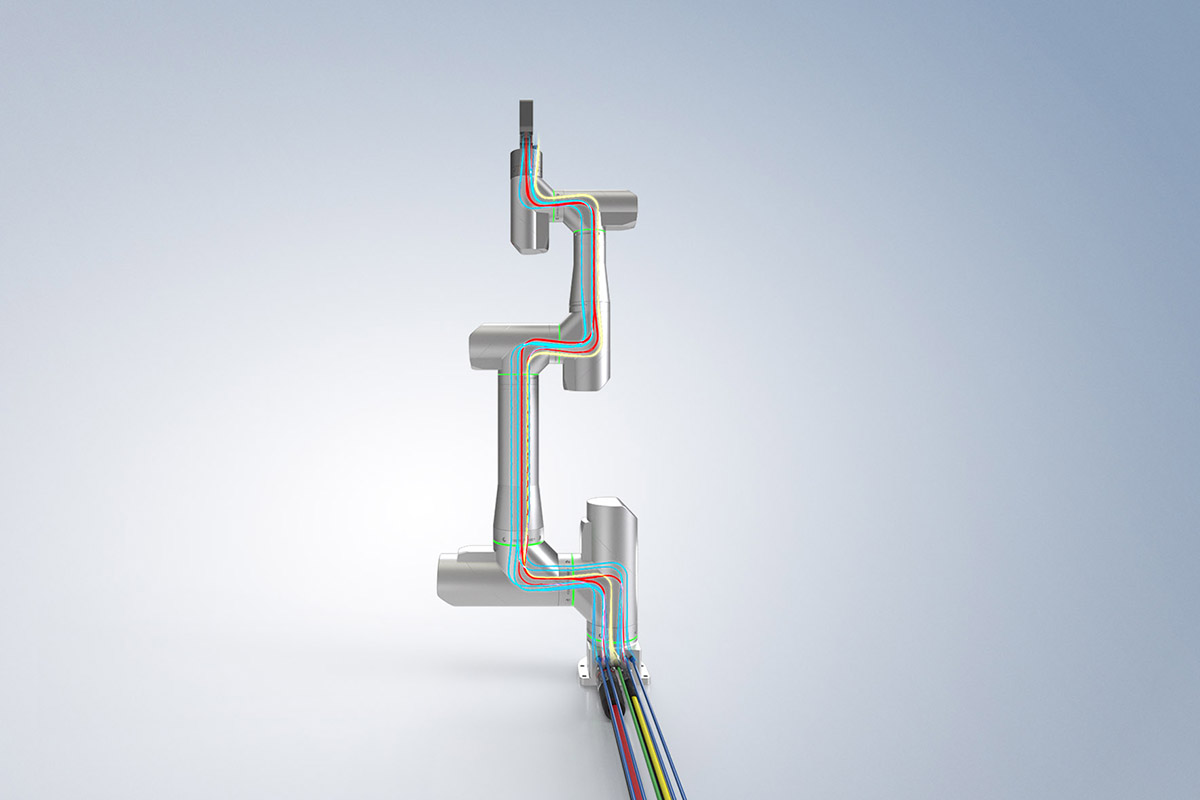

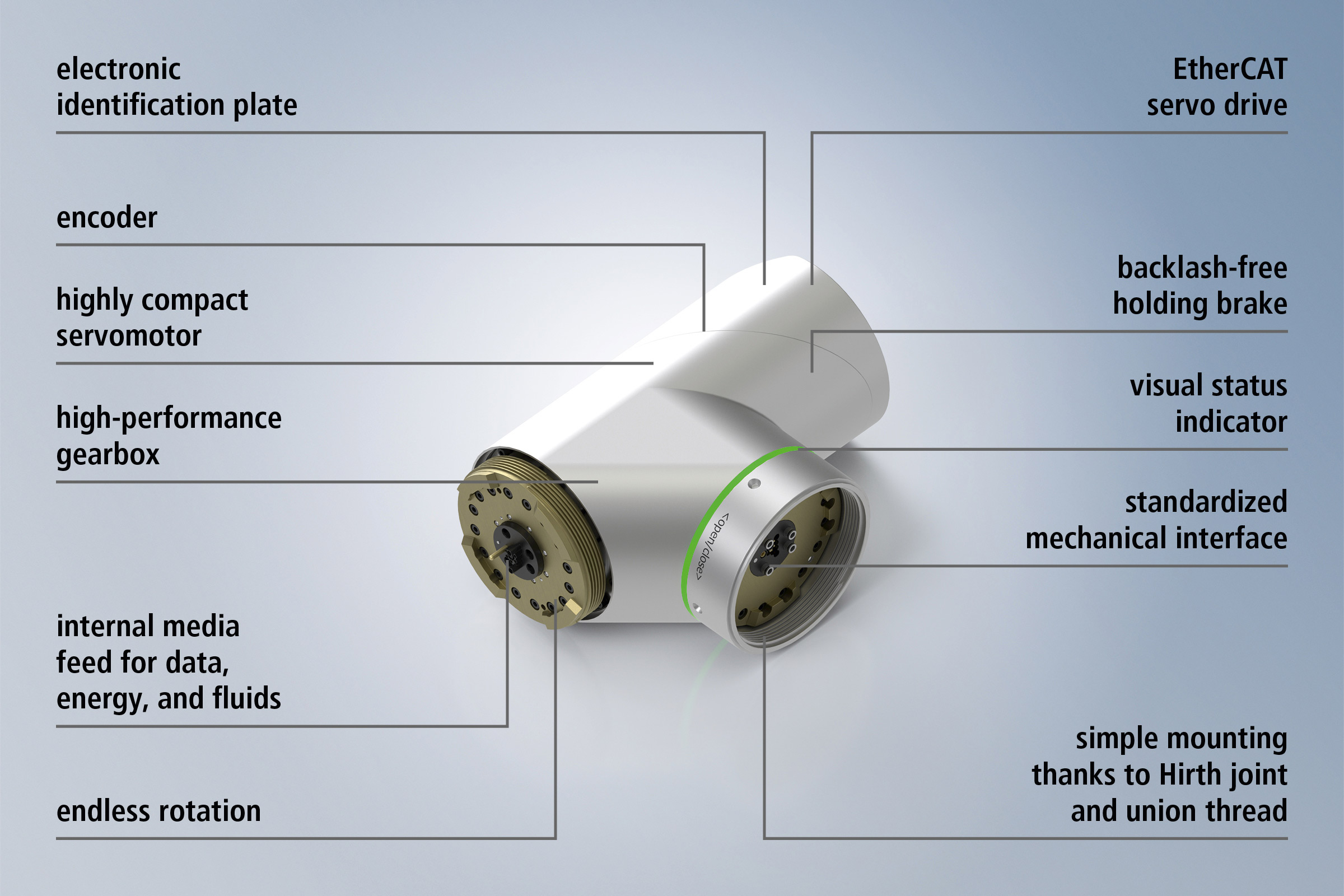

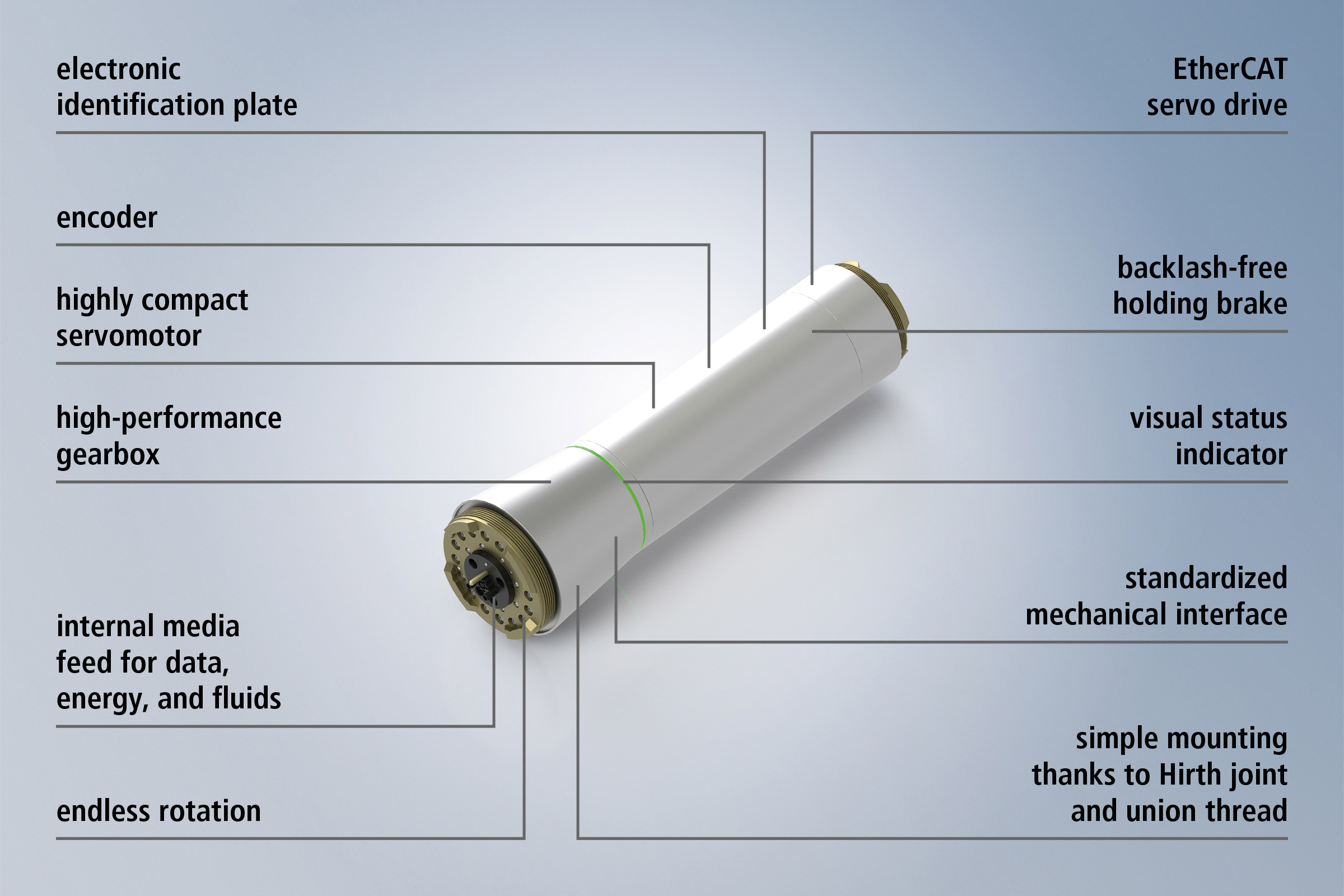

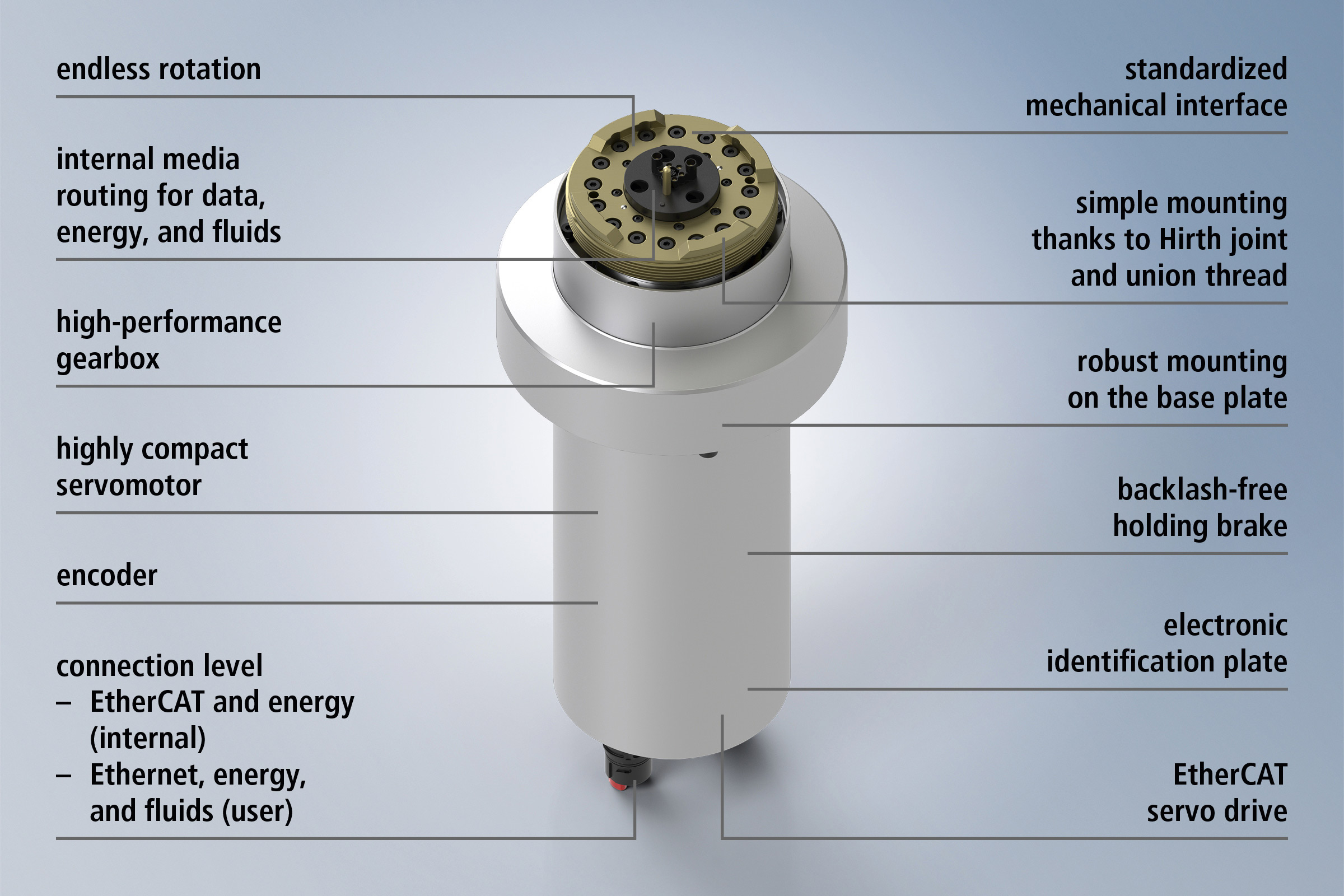

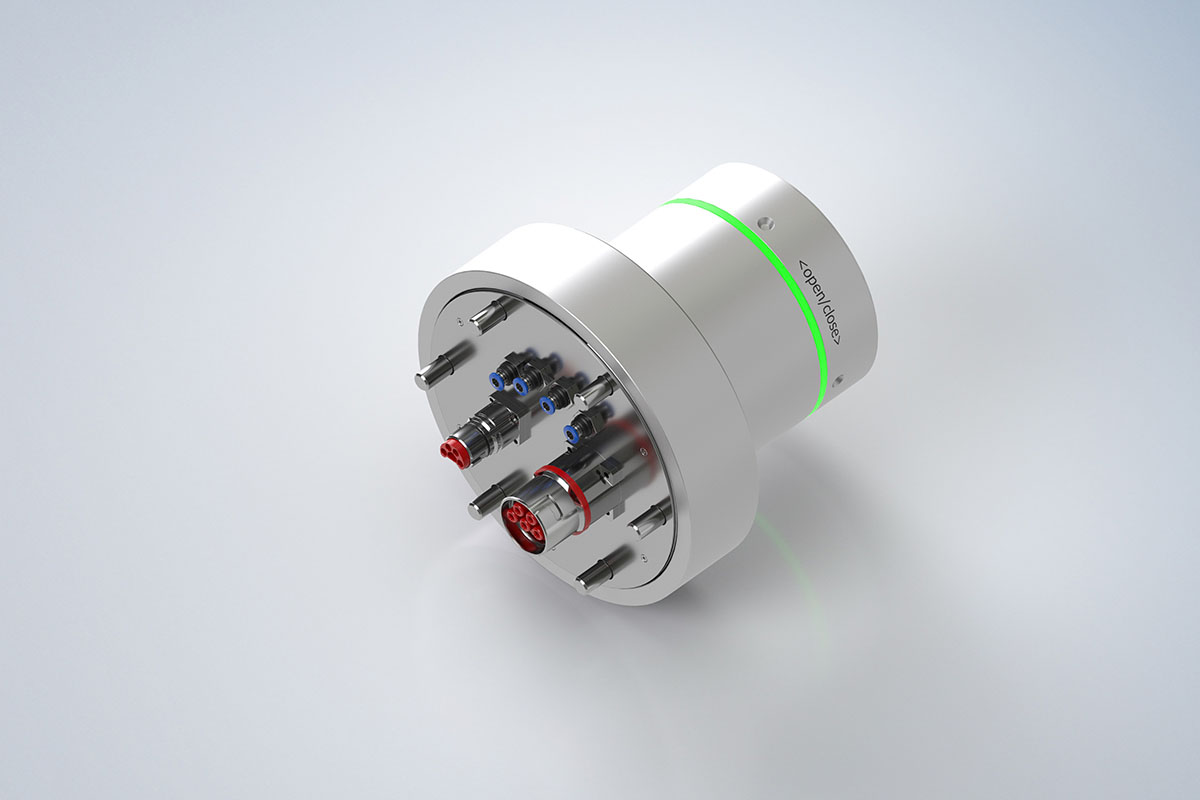

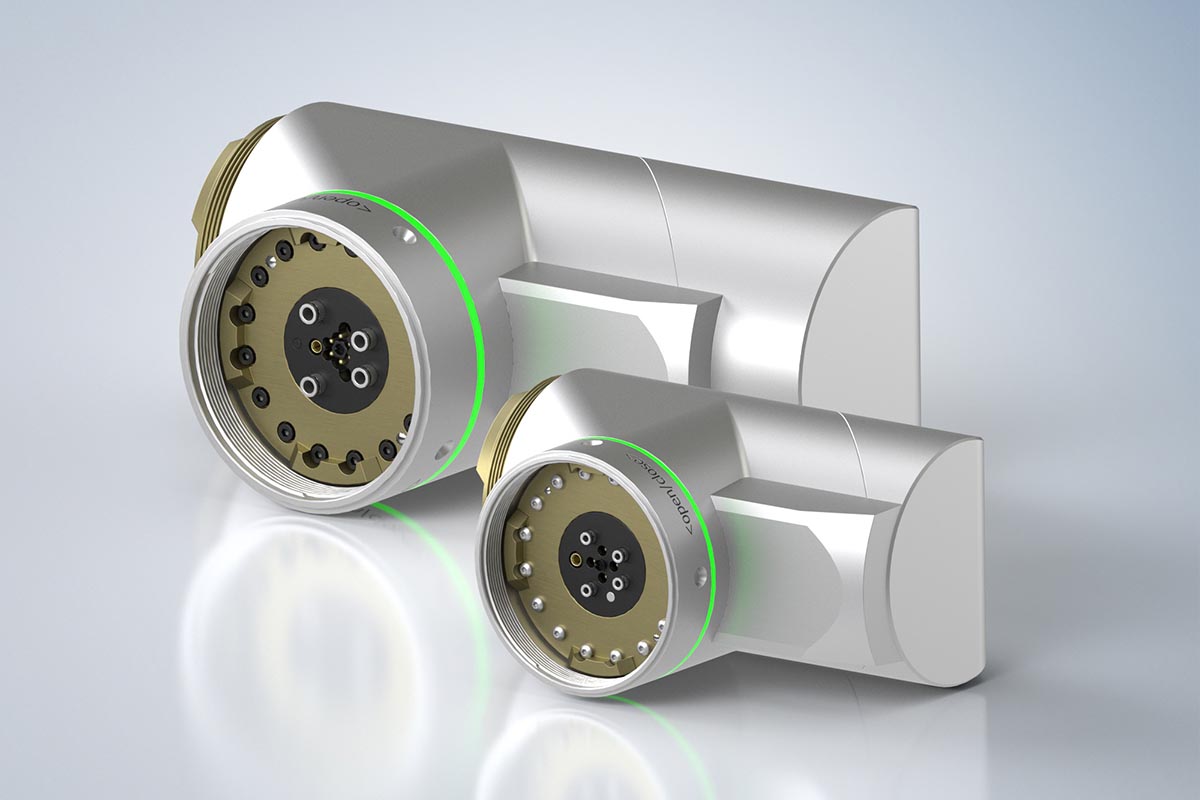

All modules feature an internal media feed for data, power, and fluids (vacuum and air), which are made available via the ATRO interface at the end effector. This means, for example, that a wide variety of tools, such as mechanical, pneumatic, or electric grippers, can be integrated with ease. Another major advantage is that all media feeds are designed so that the axes and the tool can rotate endlessly.

The modular and scalable features of the complete solution ensure both the future compatibility and investment security of the machine. The robot can be used flexibly on different machines and the application can easily be adapted to the new task.

A complete powerful package in a minimal footprint

ATRO robots are seamlessly integrated into the Beckhoff architecture, which allows them to be directly combined with intelligent transport solutions such as XTS and XPlanar. This extremely powerful complete package can now be configured on a compact machine design, thus minimizing the footprint. All components are fully synchronized through EtherCAT. Highly dynamic pick-and-place applications are no problem – as with EtherCAT, coordinated motion is performed on the fly.

Boxes of different sizes can be fed from a warehouse to one or more robot stations flexibly and individually using an XPlanar system. The products in the boxes are identified and located by the vision system and picked by the robot. After separation, the products can be sorted into shipping cartons within a running transport stream on a roller conveyor. Synchronization is performed e.g. by the EP7402 EtherCAT Box module acting as the MDR drive (motor-driven roller) for the roller conveyor.

The payload and reach of the robot are determined by the application. Using a multi-arm robot configuration can also increase the throughput of this pick-and-place application, so that there is always one arm available to grip a product. A palletizing robot stacks the finished boxes at the end of the line; these same robot modules can be used, but can now be operated in a 5-axis configuration.

What are the benefits for your overall system?

Expanding the Beckhoff control platform with robotics means that machine builders and customers can secure a complete automation solution from a single source. What’s more, integration into the Beckhoff system architecture means users now only need a single control system for all robot applications. The link with XPlanar and XTS, as well as the simple integration of all Beckhoff components into the robotics system, lays the foundations for completely new machine concepts. The open control architecture increases investment security, while EtherCAT technology also opens the door to real competitive advantages.

The modular Beckhoff robotics system offers complete freedom in terms of robot configuration. The scalable and easily pluggable motor and link modules make it possible to create customized robot solutions that can be expanded and modified at any time. Machine builders can implement their own kinematics, while customers can quickly and easily adapt their robot solution to changing production conditions at any time. The adapted structures are scanned by the control, and the TwinCAT robotics functions automatically create the corresponding control application – including a digital twin.

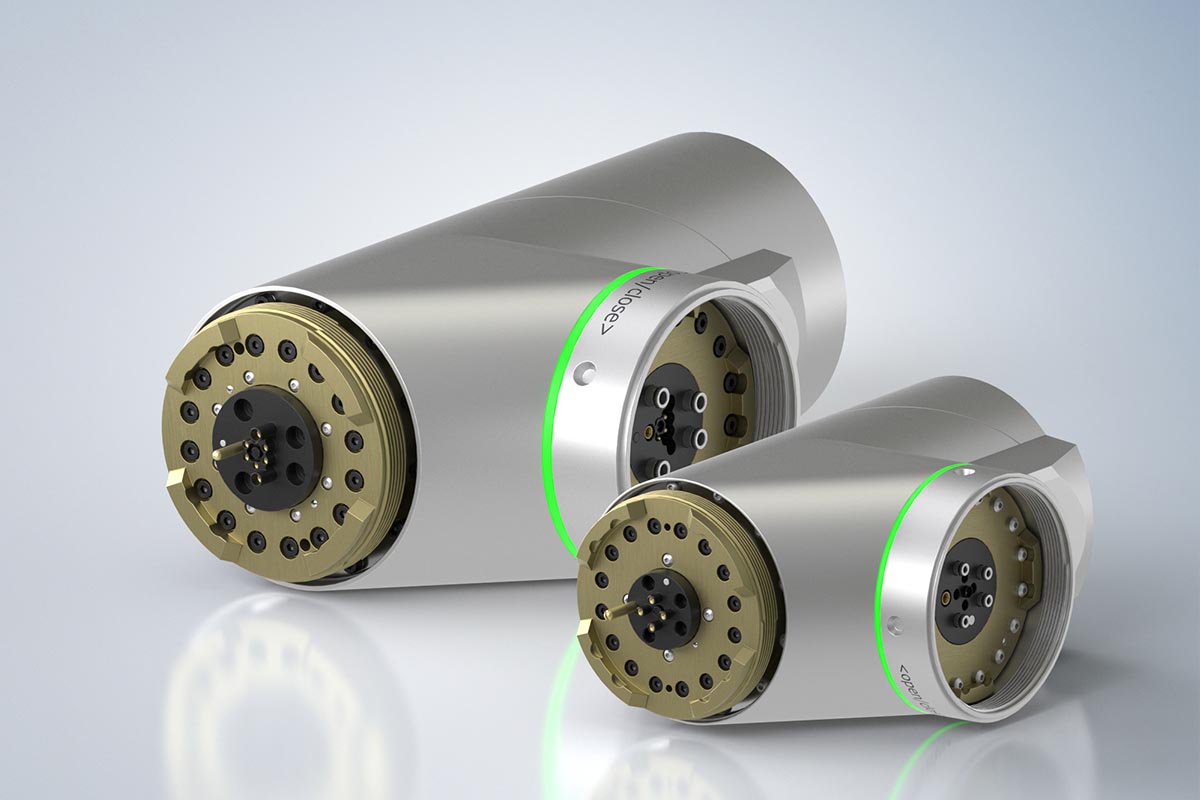

All of the electronics needed to control the axes are built into the motor modules, including an EtherCAT-based servo inverter, the motor complete with brake, and a highly compact gearbox. This reduces the robot controller to a simple control, or else integrates it into the existing machine control system.

In Beckhoff robots, fluids, power, and data are all routed internally. Conventional robotics solutions, on the other hand, route these externally and are therefore limited in terms of rotation and use of the workspace. With the Beckhoff solution, this restriction is completely eliminated, allowing each joint to rotate endlessly. This shortens the routes for the application, since no external media feed has to be ‘turned off’.

By expanding the Beckhoff portfolio with the ATRO modular plug-and-play robotics system, machine builders and users have the opportunity to implement fully integrated automation solutions for the first time. The benefits of the holistic system concept are twofold: Firstly, it features optimally matched software and hardware components from a single source, from the machine’s power supply to the modules. Secondly, all functions such as robotics, vision, safety, cloud robotics, and machine learning are fully integrated on a single control platform.

The robot solution is seamlessly integrated into the Beckhoff architecture, which enables direct combination with intelligent transport solutions such as XPlanar and XTS. This not only facilitates the configuration of an extremely powerful and comprehensive package with maximized output, but it also gives rise to previously inconceivable and extremely compact machine designs with a significantly reduced footprint. All components are fully synchronized through EtherCAT. Highly dynamic pick-and-place applications are no problem – as with EtherCAT, coordinated motion is performed on the fly.

The ATRO system also benefits from the familiar open control architecture, meaning it can be connected to all conceivable interfaces in cell/plant communication (PROFINET, EtherNet/IP, OPC UA) or to the cloud.

As a high-performance fieldbus system, EtherCAT is of course used to control the modules in sub-millisecond cycles. This also makes for easy integration of I/Os, feed axes, and/or the ATRO interface, whereby standard grippers from different manufacturers are connected via adapter plates.

Products

XTS | Linear product transport

As an intelligent transport system, the eXtended Transport System enables flexible motion profiles and new types of machine concept.

XPlanar | Planar motor system

Multi-mover 2D product movement with up to six degrees of freedom – floating, contactless, and intelligent.

TwinCAT 3 Kinematic Transformation

The integration of the robot controller into the automation software: execution of PLC, motion control and robotics on one Industrial PC.

Machine learning – for all areas of automation

Beckhoff offers a machine learning (ML) solution that is seamlessly integrated into TwinCAT 3.